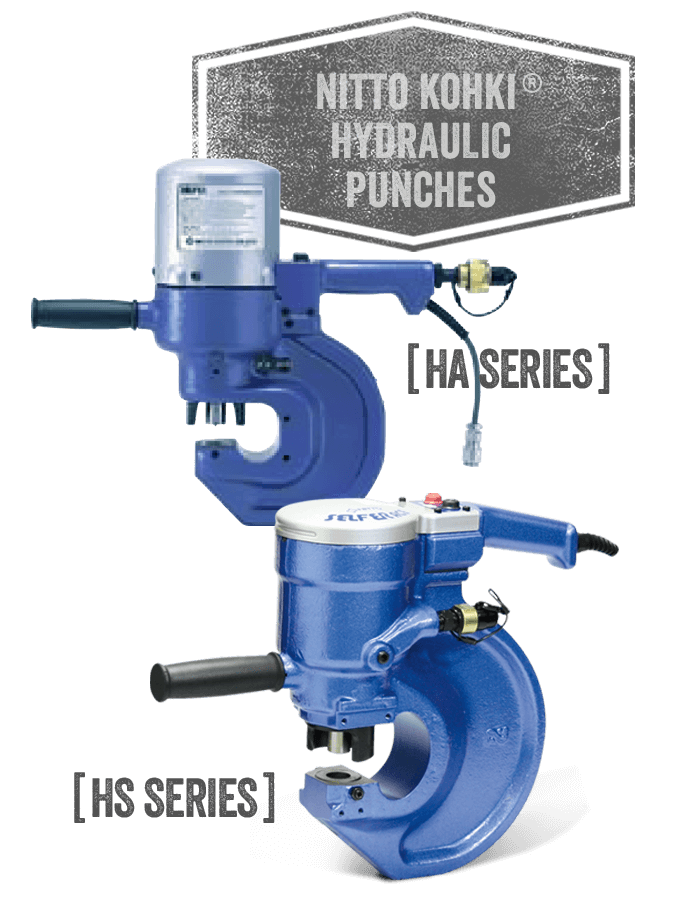

Hydraulic Punches 360

Simply by adjusting the mold, you can process many different types of holes.

It can punch any shape of holes, such as square, round or rectangular, H type e.t.c, in a square rectangular tube flat, flat, or angle.

For punching holes of any shape, such as squares, rectangles, squares, and H types e.t.c.

Gulf States Saw & Machine Co. has portable hydraulic punches, both double-acting, that offer a mechanized process for punching and reverting via its inbuilt dexterous controller device. This control device also includes inching (manual) and automatic load recognition.

Numerous industries use hydraulic punches. They can save time, provide excellent cycle times and are easy to use.

GSS Mchinery’s range of portable double-acting hydraulic punches is perfect for speedy productions of holes and slots in various materials such as beam flanges, angle, channel, plates, and bar stock.

Simply by adjusting the mold, you can process many different types of holes.

It can punch any shape of holes, such as square, round or rectangular, H type e.t.c, in a square rectangular tube flat, flat, or angle.

The high coherence of the mechanized processing piece/product is outstanding, and the product quality is even more safe.

GSS Machinery's Portable Hydraulic Punches can be used to quickly produce holes in bar stock, beam flanges and angle flanges. The Double Action design of this steel hole punch reduces cycle time and promotes material handling that is more efficient than other processes.

Our Porta Punch is the fastest way to punch up 13/16” round holes in 3/8” mild steel. It's also very strong with a maximum tensile strength at 65,000 psi.

Our Porta Punch Package comes with the 35 Ton C-Frame and an electric/hydraulic pump. Choose from 1/4", 1/2", 3/8", 7/16", 8", 7/16", 9/16", 9/16", 5/8",11/16", 3/4", 25,/32", 13/16" Punch sizes.

Our portable single-acting hydraulic punches are vastly used in the electricity industry, construction, and various outdoor fieldwork. It allows a maximum punching thickness of about 16mm, a maximum punching diameter of 24mm, and a maximum throat depth of 110mm.

GSS Machinery supplies hydraulic punches for cutting and forming sheet metal. GSS Machinery is the most trusted distributor of high-efficiency hydraulic punches. These punches can be used to make precise and smooth punches in very short periods.

Our Porta-Punch punches up to 13/16 inch round holes in 3/8" thick mildsteel with a MAXIMUM strength of 65,000 psi.

Our Porta-Punch is the quickest and easiest way to punch up to 13/16" Round Holes in 3/8" thick mild steel with a MAXIMUM tensile strength of 65,000 psi.

A punch press has two cooperating components: the punch, which is attached to the machine's reciprocating ram, and the die, which is clamped onto a bed or anvil with a flat surface perpendicular to the ram's path. When in use, the punch pushes against the workpiece held in the die.

The combination of ease of hydraulic operation and precision-ground knockouts results in clean, quick holes. Pumps are available with either foot or hand pumps. 3-point punch/die sets that are precision-ground.

Hydraulic punches are used to create round, square, or oblong holes in metal. They are intended for use with mild steel, nonferrous metals, and some plastics (non-shattering). Hydraulic punches can be powered by hand pumps, air/hydraulic, gas, or electric pumps capable of producing up to 10,000 psi (700 bar).